Yard Management Module

Our Yard Management module was designed from the ground up to offer the features that a modern container yard needs.

Everything about the module is designed with ease of use and a fast workflow in mind. The information you need to gate vehicles and assets in and out of your yard is always at your fingertips.

Intutive gating

In a fast paced yard environment, you need a gating system that puts the right information at your fingertips.

Our gating mudule intuitively checks data as you enter it, speeding up the process and minimising human error.

Enter a reference and the system will drive you towards the correct customer assets. See at a glance who's in your yard and match them with the correct inventory.

And coupled with our new VBS module, gating in is now even faster for pre-booked hauliers.

Comprehensive Notifications

All gate movements can be tied to customer notifications, both into and out of your yard.

Notifications can be created and maintained manually or automatically. Our system uses industry standard EDIFACT messages - it can receive COPARNS from your customers and send them CODECOs when their assets gate in or out.

Set up hauliers to receive notifications and they'll get an email receipt for every asset they drop off.

Reporting

Keep customers up to date with stock levels and asset movements with our automated daily reporting.

Measure KPI with ease. Standard reports offer average turnaround and more. All data grids incorporate comprehensive filtering and Excel exporting, giving you the freedom to find any data you need.

Stock queries, movement searches and more are just a customer click away, leaving you to focus on day to day operations.

Container handler

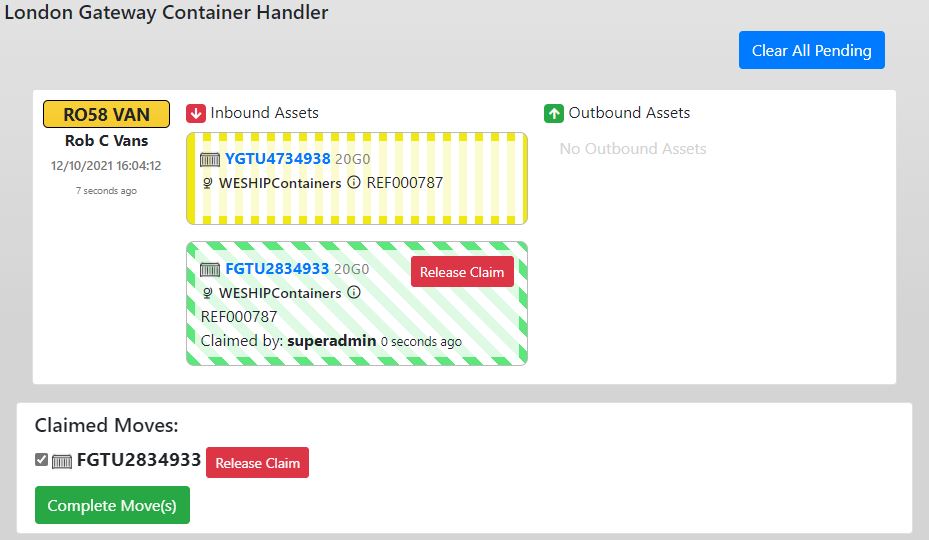

Our new Container handler feature allows lifter drivers direct access to the system so they can control their moves in real time using a tablet in their cab.

As each driver 'claims' a container that needs moving, the tablet display in all the other lifters is immediately updated to show who's picked the container. When picking units for release, the lifter driver can choose from a list of known containers of the right type, reducing human error - no more mis-hearing over crackly 2-way radios!